HUAYIDE is the China leading warehouse ASRS (Automatic Storage and Retrieval System) manufacturer and integrator. We deliver fully automated warehouse system, intralogistics solutions for Distribution Centers and Production Facilties. Whether it's maximizing storage, double the throughput, product retrieval, reducing the logistics costs, optimize material flow or rotating products, HUAYIDE is ready to find the right solution fit for your business type.

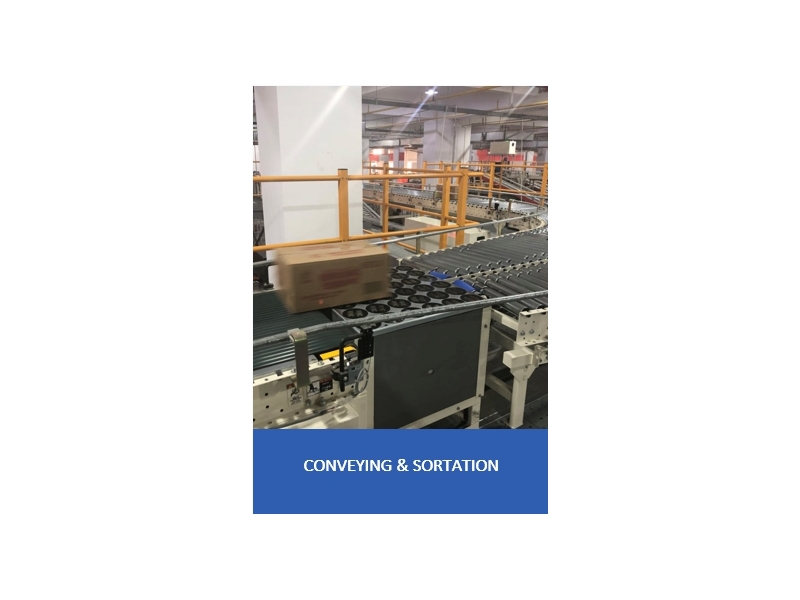

Most equipment/technologies we using in our solutions are fully developed, engineered, produced and executed by us, we develop flexible solutions tailored to various need from clients with rapid response to intimate and thoughtful aftersales service. Strongly driven towards technical innovation, HUAYIDE pay special focus on equipment manufacturing, including AS/RSs, High Density Storage Shuttle Rack System, Pallet Conveying, Picking & Sorting system, Automatic Trailer Loading System (ATLS).

We are constantly looking for Regional Partners I System Integrators located in worldwide markets. For partners and integrators, we offer discount to increase competitive, provide warranty to guarantee quality, promote training to enhance value, work closely and face together the challenges of the future and to reach cutting edge solutions, going beyond and making innovation real.

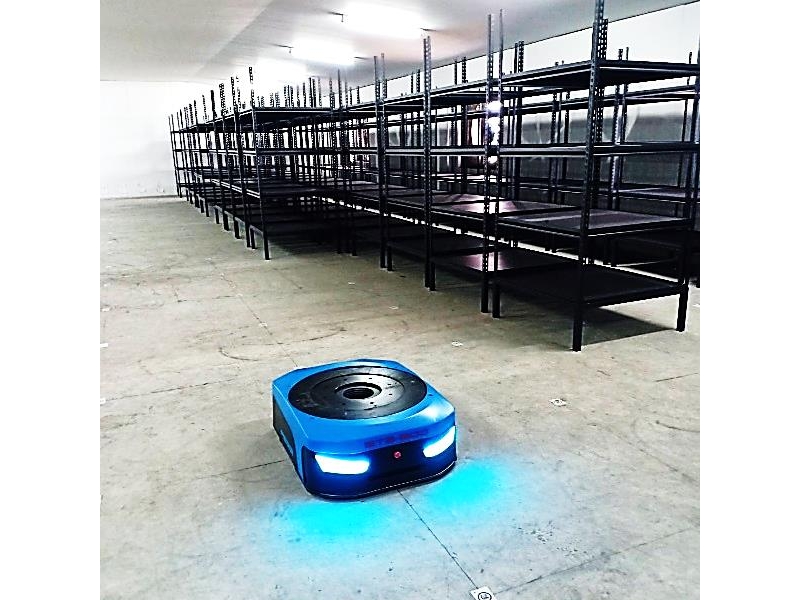

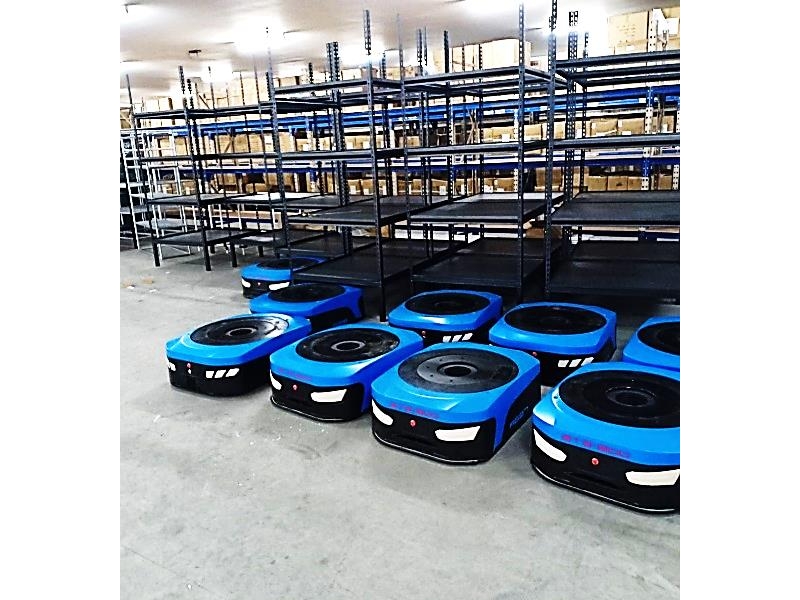

Automated Guided Vehicle

E-commerce is the hottest field in the internet industry. In the fiercest competition, for B2C dealers, the management ability in the supply chain is the bottleneck problem they want to solve, also the core competitiveness to stand out. The essence of management of the benign supply chain is to react to orders by predicting customers’ needs. Therefore, it is a challenge for the efficiency in delivery center, so the warehouse robot, an automatic technique, is applied to grasp and move goods shelves and goods, send goods to the picking staff for package and delivery. This is an effective way to improve picking efficiency in the warehouse, reduce employees for cargo handling and achieve warehousing automation.

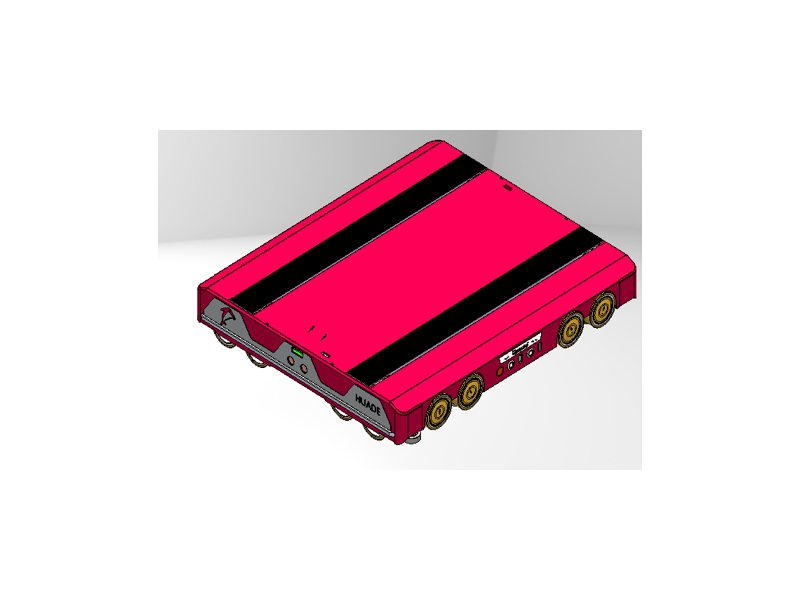

4-way Shuttle

a) 7000-10000 Baht/Pallet

b) Sku is a relatively small warehouse, warehouse space utilization is large

c) Intelligent four-way shuttle shelf system is mainly used for the automatic transfer of pallet cargo to the warehouse.

d) Can be used on the shelf track, can also be used on the ground, not limited by the site, road, slope, fully reflects its automation and flexibility characteristics;

e) Automatic pick-up, automatic lane change, intelligent leveling, automatic climb, directly to any location in the warehouse;

f) Each laneway can flexibly configure the number of storage layers, storage of a large number of different types of goods;

g) multi-layer shuttle. Expand with multi-layered technology to meet customer needs and achieve on-arrival picking

h) Store dual-loop jobs. Four units can be moved simultaneously in one cycle, resulting in high operating efficiency

i) The shuttles are equipped with separate lifters and conveyor lines for sorting without the need for additional buffer warehouses

j) This is an intelligent storage system with automatic handling, unbooted and intelligent control

k) It is convenient to form advanced logistics system and improve the level of production management

l) All warehouse operations are mechanized and automated, on the one hand, can greatly save manpower,

reduce labor costs, automation of three-dimensional library on the other hand also greatly improve the efficiency of operations.

m) Automated stereoscopic library using computers for warehouse management, can easily achieve "first in, first out“

to prevent the natural aging of goods, deterioration, rust, to avoid the loss of goods

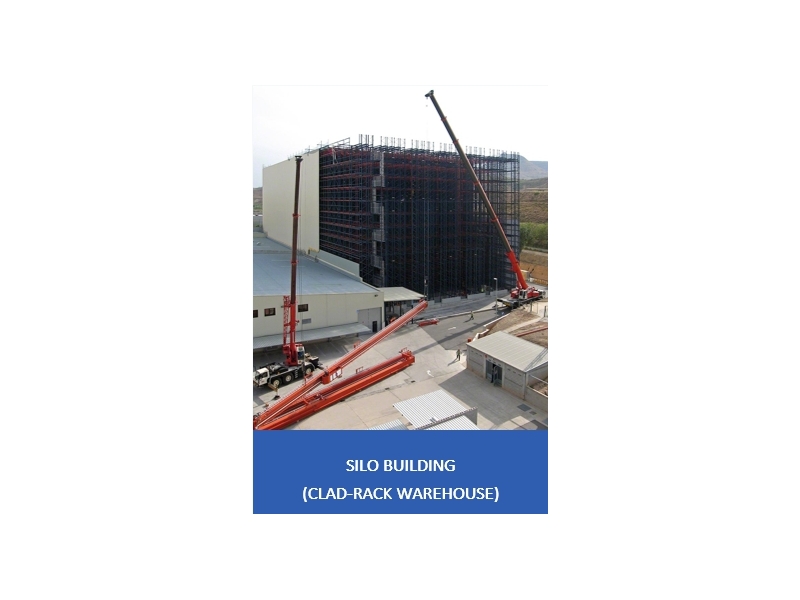

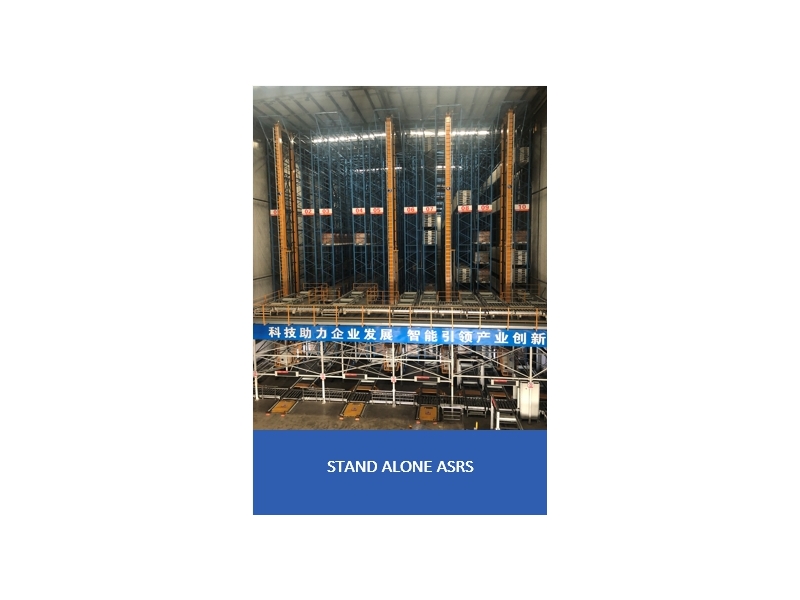

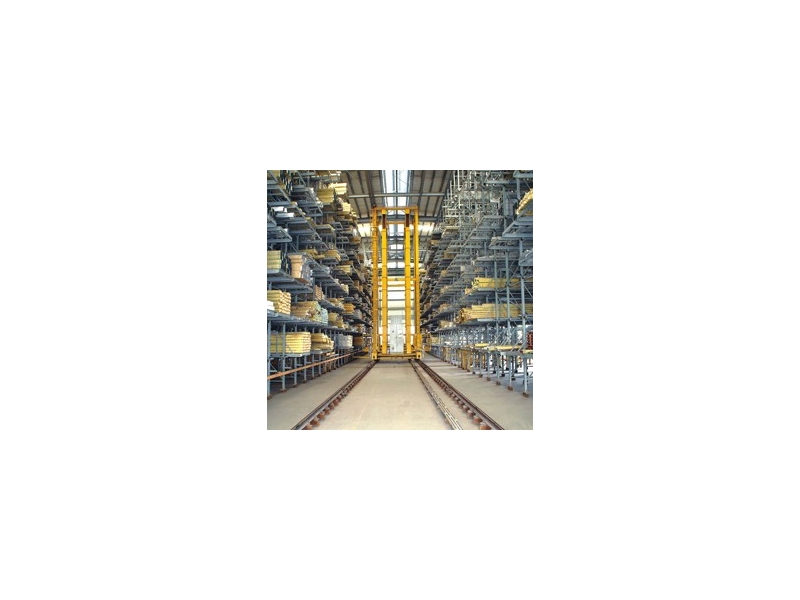

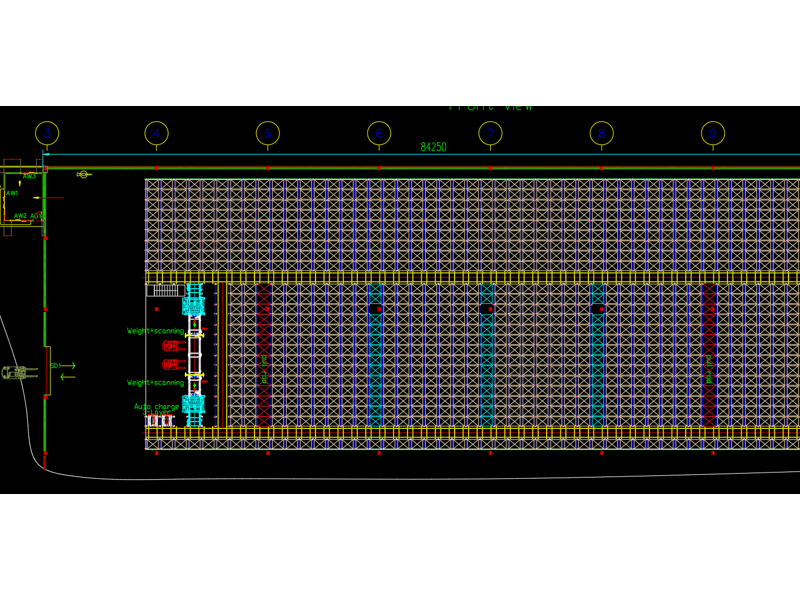

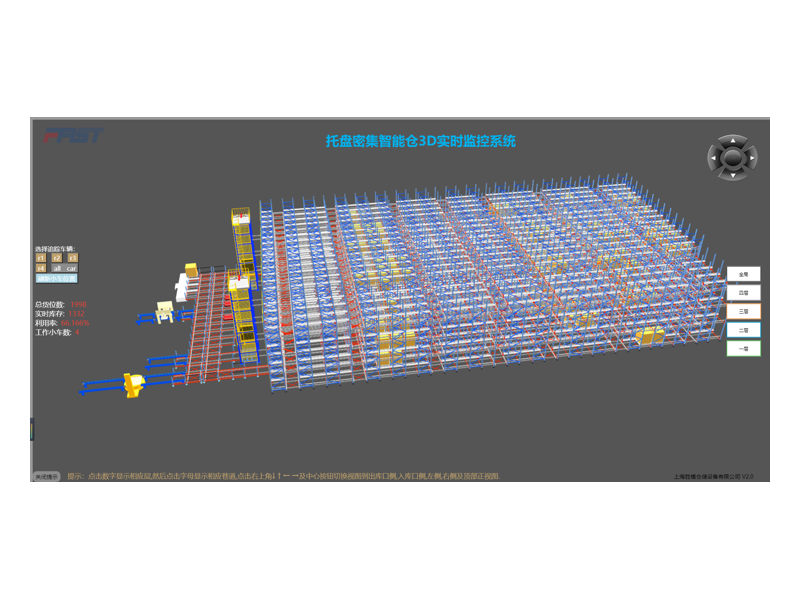

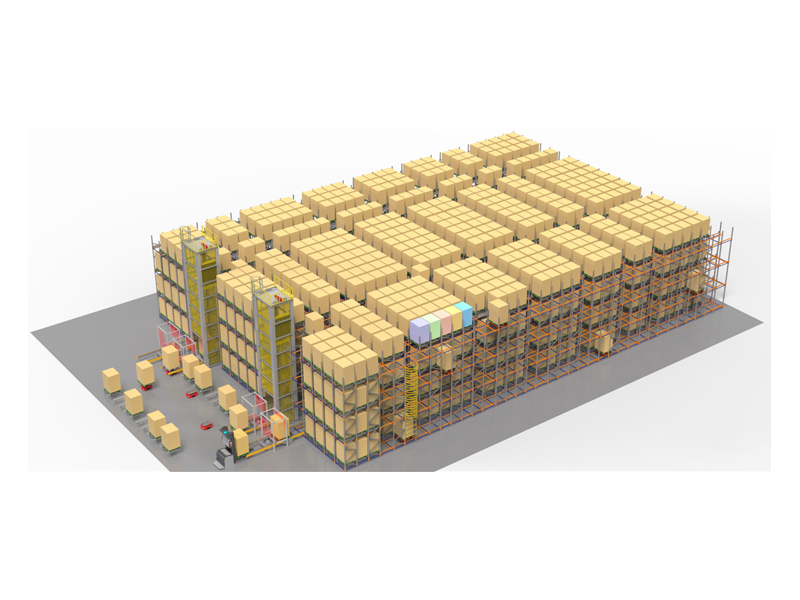

AS/RS

a) 8500-20000 Baht/Pallet

b) The warehouse is high

c) Need mechanical tracks

d) Make full use of the vertical space of the warehouse, automated three-dimensional library greatly save manpower, the use of computers for warehouse management, better adapt to the dark, low temperature, toxic and other special environment requirements, significantly reduce the rate of damage to goods

e) Automated three-dimensional library can make full use of the vertical space of the warehouse, its unit area storage capacity is much larger than the ordinary single-storey warehouse (generally 4-7 times the single-storey warehouse). Currently, the world's tallest stereoscopic warehouse can reach more than 40 meters and can hold up to 300,000 storage spaces.

f) All warehouse operations are mechanized and automated, on the one hand, can greatly save manpower, reduce labor costs, automation of three-dimensional library on the other hand also greatly improve the efficiency of operations.

g) Automated stereoscopic library using computers for warehouse management, can easily achieve "first in, first out" to prevent the natural aging of goods, deterioration, rust, to avoid the loss of goods

Mobile Rack

a) 6000-8000 Baht/Pallet

b) The space is small

c) Semi-automatic

d) There are no wms and wcs systems

e) good for small cooler store

แกลเลอรี่

แกลเลอรี่